Various areas of responsibility go into everyday running of a platform or FPSO. Services, Process, Maintenance, Construction, HSE - with these all multiplied again with vendor inputs

PPP will tie these elements together, from their separate sources: SAP / Primavera / MS Project / ISSOW / Scaffold auditing / Lift plan auditing / Progress & compliance reporting - an integrated centralised planning infrastructure

"To begin the plan incorporated with the data sources, rather than attempting to replicate in each one after"

linking HSE COMPLINCE to plan

"Why am I only getting 6 hours productivity per shift from the crew?"

A typical scene of the invariable queue around the Area Authorities desk!

The two people standing on the right of above screen are logging their forthcoming work into their permit-to-work system. The person on the bottom left is the area authority, who takes preliminary steps to acknowledge these requests. The AA will then review each of the day’s requests in a meeting with platform management before the work is authorised. In this normal scenario the authorisation to do the day’s planned work is delayed by several hours, and sometimes by days. Normally the planner and the area authority operate completely independently of each other, planning and safety operating independently of each other.

The plan is the vision

The permit-to-work is the gateway

Does your area authority know what's coming at him, when?

Are your plan and permit-to-work system integrated????

PPP will integrate the two, and train the users

In above illustration, the screenshot on the left is Primavera and the one on the right is ISSOW, the standard North Sea permit-to-work database. Because on this PPP project the systems were integrated from the start, the permit number and status are visible and integral to the progress of the plan

Integrating vendor projects to main plan

You will have independent vendors for:

Construction/Fabrication

Inspections

Maintenance

Subsea

If they are independent:

Who reports OVERALL progress?

PPP will provide you with tools to integrate codes, calendars, reporting

One project, one histogram, one plan, one s-curve

(Click arrows for next image)

In above carousal we have POB histogram broken down by department as left image.

Right image is daily Plan V Actual S-Curve hours by department

Services are the "unknown, unknowns" of large projects

Invariably project leaders are from operations, maintenance, or construction background.

What are the elements behind lift plan preparation / scaffold erection and maintenance / insulation removal?

Have you got full visibility of the indicators behind these key elements of plan readiness?

Beyond number of men x duration?

Documentation (calculations, P&ID) / inspection (how often?) / internal v external v overside / request date v required date / tonnage / type / material requirements

PINPOINT PLAN can take and record all of these individual elements and summarise them to Primavera to provide a "readiness" dashboard

As in below carousel of images, where last image is a dashboard records for scaffolding / rigging / insulation / permits per work order

(Click arrows for next image)

Furthest left screen is from a scaffold request system, the middle screen is from a lifting plan system, the furthest right screen is a layout in Primavera of the project these relate to. Each job has multiple services associated to it, material availability being another example. PPP can integrate any version of these into a traffic light based dashboard showing overall status of job readiness - each row is an independent job, the indicators showing prep stage of service in column header (blue means NA)

Previous Projects (some examples)

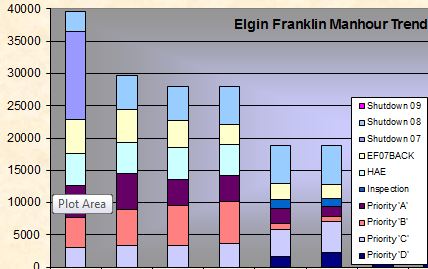

Elgin Franklin Field, Total - Built Total’s offshore reporting and scheduling system. Integrated Primavera, SAP and ISSOW. Integrated Primavera reporting with reporting for HSE compliance, reports for percentage complete of related lifting plans, scaffolding plans, and maintenance KPI for sub-contracting companies

North Alwyn Field, Total - Alongside Elgin Franklin and Dunbar, changed Total’s offshore planning and reporting template. Produced projects scheduling system to control work across various sub-contractors for maintenance, inspections and fabrication - (Wood Group, Aker Kvaerner, Petrofac, Bureau Veritas etc)

Everest, Armada, Lomond, BG Group/Shell - Integrated ISSOW, Maximo, Primavera and AMEC construction jobcard system (JMS). Built company planning infrastructure monitoring FEED to execution, including vendor management (AMEC, Stork, Talisman, etc).

Ivar Aasen fabrication, Det Norkske, Sembcorp Marine Offshore Engineering, Wood Group - Brought in at final stages of fabrication to provide better visibility of Remaining Engineering Scope and Remaining Life Cycle Information. Integrated Pacesetter, Citadon and SharePoint document systems ensuring compliance standards, ensuring sail-away remained on track

Tengiz Expansion Project, Kazakhstan Govt, Chevron, Honeywell, Mustang - $35 billion project. Automation work coordinated between Pune, Ayrau, Tengiz, Seoul and Woking. Built data management system monitoring Spend v Earned (Budgeting). Standardised WBS across plan/timesheets/reports - spanning cost codes, RIEs ( remote instrument enclosures project based on), hardware/software, phase, and discipline

Are your key statistics from separate sources?

S-curve, backlog, compliance, & HSE KPIs all tend to be owned by different departments.

During Pinak's Elgin Franklin years, he automated Total's backlog and compliance reports. Which gave superintendents/discipline leads/planners the capacity to run these reports from their desktops. And look into their detail, rather than just have the numbers prescribed to them from the SAP department. Which led to improved housekeeping.

Priority A = Safety Critical, Priority B = Production critical, Priority C = Production non-critical, Priority D = Routine

Backlog and compliance are often considered inferior sciences amongst engineers, normally preoccupied keeping the platform safely producing. But in times of low barrel value, when statisticians consider platform decommissioning, backlog is a key indicator of the NPV of an asset.

Consider the value of 20,000 man-hours, as above images depict the reduction of backlog to have been, in just a few months of housekeeping, in monetary value. (If the average shift has 7 hours productive per man, this is 2,857 man days)

2857 man days, with a 2x3 rota, is 20 men for one year. If they have average salary £50K, this is £1,000,000 in labour alone

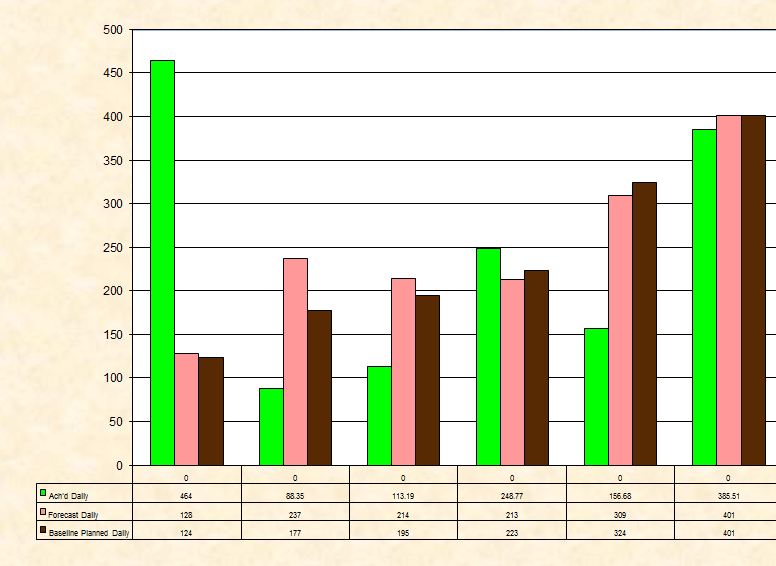

Integration is key not just within the company, but also with vendors on large projects. As mentioned in vendor integration section, many different areas of large projects have plans individually articulated. But integration is key to overall visibility of plan v achieved.

The above illustration depicts stats from a project including work scopes - safety maintenance, construction, fabric maintenance, inspections, electrical, instruments, mechanical, operations

talks + events

Beurs World Trade Centre - Rotterdam

- Beurs World Trade Centre - Rotterdam, 23rd - 25th February

- Pinak Pushkar (MD) will chair "STO Europe 2015"

- Speakers will include representatives from:

- IBM Consulting

- Evraz Nikom

- Emerson

- Centrica

- Tata

- Shell

Pinak Pushkar - MD

Email: ppushkar@pinpointplan.co.uk

Twitter:

@pinpush

-

Fruitful few days chairing Shutdown and Turnarounds Conf in Rotterdam, learnt a lot http://t.co/sVIMmI1cZZ

-

Looking forward to charing STO conference Tuesday and Wednesday in Rotterdam!